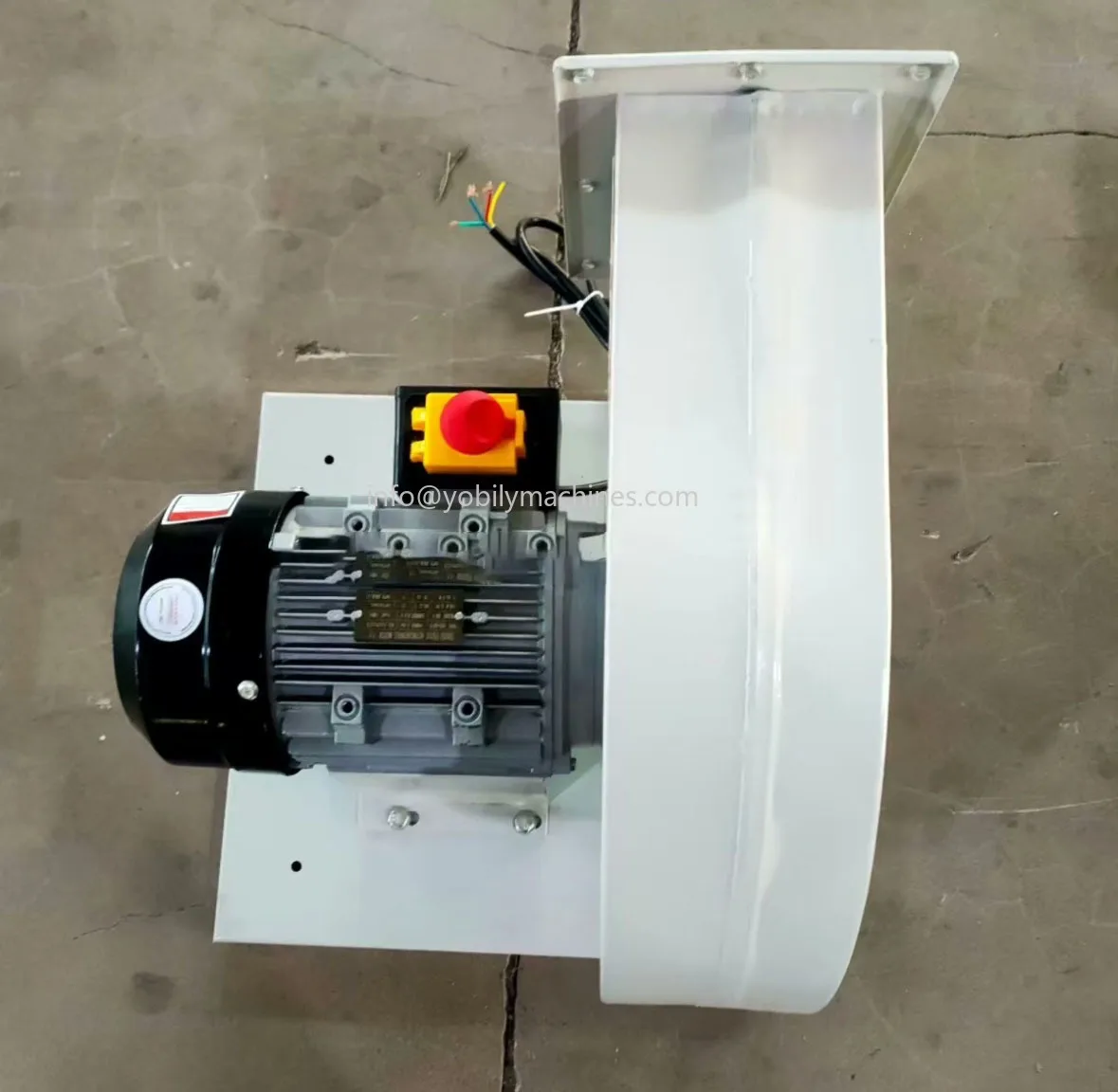

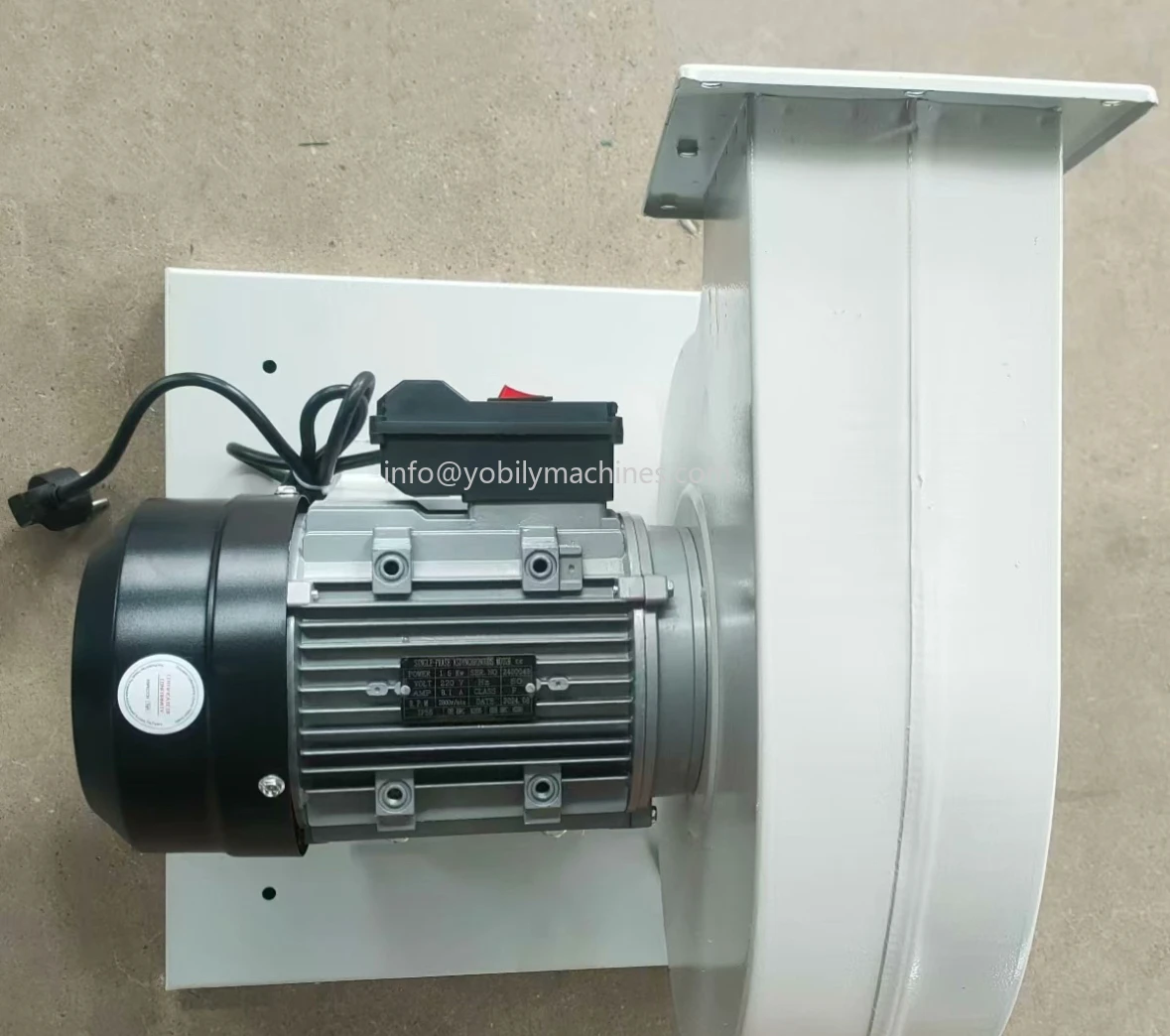

T33587 1HP Mini Portable Dust Collector/Wheeled Dust Collector with Handle

Rp17.578.605

In Stock

Description

- Hign-concerned Chemical: None

- Origin: Mainland China

- Cord Length (m): About 4 meters

- Certification: CE

- Dust Box Capacity (L): >2 L

- Voltage: 220 V

- place of origin: Fujian, China

- brand name: Yobily

- machine type: wood dryer

- video outgoing-inspection: Provided

- machinery test report: Provided

- core components: Engine

- warranty: 1 Year

- weight (kg): 18

- power (kw): 0.75

- Power: 0.75KW

- Filtration accuracy: 5 microns

- Weight: 18gs

- Size: 440*410*420mm

Specification

Dust collector mainly to solve the problem of indoor production processes where dust source and more . Can be used in the pharmaceutical , powder blending and powder charge the food industry(Or powder packaging)Jobs; furniture manufacturing. Leather,rubber industry, environmental protection equipment of choice.

Mobile dust collector bag Features: This cyclone dust collecting machine adopts expertise with the vacuum cleaner bag , suction is particularly strong.

Mobile dust collector bag uses: near places collecting dust, no piping, save money, a substantial increase in convenience and mobility Sex. Suitable for sandblasting, grinding, woodworking, grinding, cutting, etc., cleaning powder, cotton dust, Sawdust purpose.

Mobile dust collector bag Features: This cyclone dust collecting machine adopts expertise with the vacuum cleaner bag , suction is particularly strong.

Mobile dust collector bag uses: near places collecting dust, no piping, save money, a substantial increase in convenience and mobility Sex. Suitable for sandblasting, grinding, woodworking, grinding, cutting, etc., cleaning powder, cotton dust, Sawdust purpose.

|

Model

|

MF9075E

|

|

Motor Power

|

0.75KW

|

|

Air volume

|

230m³/h

|

|

Air inlet size

|

100*2

|

|

Bag size

|

370x640mm

|

|

Package Size

|

440*410*420

|

|

Dimensions

|

1100*400*410

|

|

Net weight/gross weight

|

20/22

|

Product Description

Company Profile

Established in 2012, we are a leading manufacturer specializing in high-performance, custom industrial dust collection systems.

With a strong focus on precision engineering and flexible manufacturing, we provide tailor-made solutions for factories worldwide,

ensuring cleaner and safer working environments.

鉁� Bespoke Designs – Every system is engineered to match your specific requirements.

鉁� Low MOQ – Accept single-unit orders with no compromise on quality.

鉁� End-to-End Service – From consultation to installation support.

With a strong focus on precision engineering and flexible manufacturing, we provide tailor-made solutions for factories worldwide,

ensuring cleaner and safer working environments.

鉁� Bespoke Designs – Every system is engineered to match your specific requirements.

鉁� Low MOQ – Accept single-unit orders with no compromise on quality.

鉁� End-to-End Service – From consultation to installation support.

———————————————————————————————————————————-

Our Expertise

鉁� Custom Dust Collectors – Designed for woodworking, metalworking, chemical, pharmaceutical, and food processing industries.

鉁� Advanced Filtration – High-efficiency cartridge, baghouse, cyclone, and wet scrubber systems.

鉁� Turnkey Solutions – Includes ductwork design, airflow optimization, and compliance with international standards (OSHA, EPA, CE).

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certifications

FAQ

1. What types of dust collectors do you offer? We specialize in custom-built dust collection systems, including: Baghouse Dust Collectors (for fine particulate) Cartridge Dust Collectors (compact, high-efficiency) Cyclone Dust Separators (pre-filtration for heavy dust) Wet Scrubbers (for explosive or sticky dust) Centralized Dust Extraction Systems (multi-point collection)

2. Can you customize dust collectors for specific industries? Yes! Our systems are engineered for: 鉁� Woodworking (sawdust, MDF, plywood) 鉁� Metalworking (grinding, welding fumes) 鉁� Pharmaceutical/Chemical (powder processing) 鉁� Food Processing (flour, sugar, starch)

3. What’s your minimum order quantity (MOQ)? MOQ = 1 unit – We accept single-machine orders with full customization.

4. How do you ensure filtration efficiency? HEPA filters (up to 99.97% @ 0.3μm) Pulse-jet cleaning (auto-cleaning for sustained airflow) Explosion-proof options (ATEX compliance for combustible dust)

5. What’s the lead time for production? Standard models: 3–10 days Custom systems: 30–45 days (depending on complexity)

2. Can you customize dust collectors for specific industries? Yes! Our systems are engineered for: 鉁� Woodworking (sawdust, MDF, plywood) 鉁� Metalworking (grinding, welding fumes) 鉁� Pharmaceutical/Chemical (powder processing) 鉁� Food Processing (flour, sugar, starch)

3. What’s your minimum order quantity (MOQ)? MOQ = 1 unit – We accept single-machine orders with full customization.

4. How do you ensure filtration efficiency? HEPA filters (up to 99.97% @ 0.3μm) Pulse-jet cleaning (auto-cleaning for sustained airflow) Explosion-proof options (ATEX compliance for combustible dust)

5. What’s the lead time for production? Standard models: 3–10 days Custom systems: 30–45 days (depending on complexity)

6. Do you provide installation support? Yes, we offer: 3D layout drawings (for ductwork planning) Remote commissioning guidance (via video call) On-site installation (optional, extra cost)

7. What certifications do your products have? CE (EU compliance) ISO 9001 (quality management) NFPA/ATEX (for explosive environments, upon request)

8. How to maintain the dust collector? Replace filters when pressure drop exceeds 6–8″ WC Empty dust bins at 80% capacity Annual motor/fan inspection

9. What’s your warranty policy? 12 months for mechanical parts 6 months for filters (wear-and-tear excluded)

10. How to request a quote? Send us: Dust type & particle size (e.g., wood chips, 50μm) Airflow requirements (CFM or m³/h) Space limitations (if any) We’ll provide a free design proposal within 48 hours.

7. What certifications do your products have? CE (EU compliance) ISO 9001 (quality management) NFPA/ATEX (for explosive environments, upon request)

8. How to maintain the dust collector? Replace filters when pressure drop exceeds 6–8″ WC Empty dust bins at 80% capacity Annual motor/fan inspection

9. What’s your warranty policy? 12 months for mechanical parts 6 months for filters (wear-and-tear excluded)

10. How to request a quote? Send us: Dust type & particle size (e.g., wood chips, 50μm) Airflow requirements (CFM or m³/h) Space limitations (if any) We’ll provide a free design proposal within 48 hours.

Reviews

There are no reviews yet.